- Home Page

- Company Profile

-

Our Products

- Braided Hose

- Suction & Delivery Hose

- PVC Antistatic Non Toxic Hose

- Lay Flat Delivery Hose (Blue Color)

- HDPE Pipes & Fittings

- PVC Pipe & Fittings

- U-pvc Casing Pipes (Blue Color)

- Threaded Plumbing Pipes

- U-pvc Pipes and Fittings (Grey - Isi-4985)

- Dutron Upvc Pressure Pipes (Grey Is-4985)

- Upvc Casing Pipes

- Upvc Plumbing Pipe (White-ASTM-D-1785)

- Moulded Fittings

- Fabricated Fittings

- Column Pipes

- C-pvc Water Pipes (Hot Water)

- UPVC Column Pipe (Ashirvad Make)

- Polypropylene Pipe & Fittings

- Acrylic / Polycarbonate Pipe

- Corrugated Pipes

- High Temperature Hose (Imported - GERMANY )

- Industrial Valves

- PP Sight Glass Valve Type T11

- NRV Non-Return Valve Type T10

- Diaphragm Valves

- Actuated Valve

- Foot Valve Type T9

- Butterfly Valve

- Ball Valve Flange End Type T1

- Ball Valve Suitable For Salt Water Type T2

- Ball Valve Suitable For Heavy Concentrated Chemical Type T7

- PP Damper Valve

- Ball Valve Screw End Type T1

- Ball Valve Suitable For Chemical Acid Type T3

- Ball Valve (Suitable For Acid High Type T4)

- Ball Valve Suitable For Abrasive Crystal Chemical Type T5

- Ball Valve Suitable For High Abrasive Crystal Chemical For Solvent Type T6

- Ball Valve Suitable For Very High. Cons. Chemical Type T8

- Rubber Hose

- PPR Pipe Fittings(Green Color)

- Plastic Sheets

- DWC PIPE

- PU Spiral Duct Hose

- Medical Gas Hose

- Welding Machine

- Pipe Floats

- PP Strainer

- Pipeline Installation Services

- Flexible Hose

- HDPE Pipe Fitting

- EF Elbow 90 (Electro Fusion) (Short Bend - 90 Deg.)

- EF Coupler (Electro fusion) (Socket)

- EF Tee (Electro-Fusion) (Equal tee)

- EF Elbow 45 (Electro Fusion)

- EF Tapping Saddle (Electro Fusion) (With Boom)

- EF End Cap ( Electro-Fusion)

- EF Stub End (Electro-Fusion) (Without METAL Flange)

- EF Tapping Tee (Electro-Fusion) (With Bottom)

- EF Transition Coupler (Electro-Fusion)

- Alignment Tool

- Saddle Holder (Support)

- Scrapper Scrapper

- Chamfering Tool

- EF Welding Machine- (Electro-Fusion) (With Printer)

- EF Welding Machine (Electro-Fusion) (Manual Type)

- EF Welding Machine- (Electro-Fusion) AUTOMATIC (Bluetooth Enable)

- EF Welding Machine (Electro-Fusion) AUTOMATIC ( Biuetooth Enable)

- Contact Us

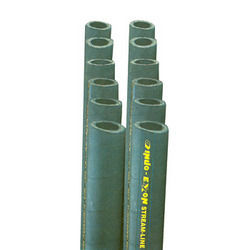

Sand Shot Blast Hoses

Product Details:

- Reinforcement High tensile synthetic textile plies with steel wire helix

- Medium Sand, Grit, Shot Blasting Media

- Hardness 65 5 Shore A

- Connection Type Plain or with Couplings

- Shape Round

- Cover Abrasion and weather resistant rubber

- Pressure 12 Bar (174 psi)

- Click to View more

X

Sand Shot Blast Hoses Product Specifications

- Abrasion and weather resistant rubber

- Round

- 32 mm to 102 mm

- 65 5 Shore A

- 19 mm to 76 mm

- Sand, Grit, Shot Blasting Media

- High tensile synthetic textile plies with steel wire helix

- Plain or with Couplings

- 12 Bar (174 psi)

Product Description

Sand Shot Blast Hoses:-

Client can avail from us a comprehensive range of Rubber Sand Shot Blast Hose, these are seamless, extra thick and soft rubber tubes. Ideal for usage for sand/shot blasting system using gravel, sand, steel ball shots in clearing metal surface, etching glass, smoothing castings and many other things. Following is the product specification:

| Tube | Seamless, extra thick but uniform in thickness and soft tube |

| Reinforcement | Textile permeated with rubber, in suitable number of plies or synthetic fiber |

| Electrical bonding | Anti-static copper wire provided for electrical continuity if required |

| Cover | Abrasion & weather resistant rubber cover |

| Temperature range | -40°F to +160°F |

| Length | Max. 18 meters |

Engineered for Industrial Demands

Our Sand Shot Blast Hoses are designed to meet the rigorous requirements of construction and industrial environments. With high tensile reinforcement and a weather-resistant cover, these hoses withstand abrasive blasting media such as sand, grit, and shot. The robust design ensures longevity even under intensive use.

Adaptable and Flexible Solution

Featuring a high degree of flexibility and a minimum bend radius of 10 times the inside diameter, these hoses enable smooth handling and installation. Choose from plain or flanged ends, round shape, and a range of diameters to ensure compatibility with your equipment, all packaged securely in poly bags or as per your specified requirements.

FAQs of Sand Shot Blast Hoses:

Q: How should Sand Shot Blast Hoses be installed for optimal performance?

A: To ensure optimal performance, these hoses should be installed following the recommended minimum bend radius of 10 times the inside diameter. Avoid sharp bends or twists, and secure the ends, whether plain or flanged, tightly to prevent leakage during operation.Q: What media can be used with these sand shot blast hoses?

A: These hoses are suitable for use with sand, grit, and shot blasting media, making them ideal for cleaning, surface preparation, and debris removal in industrial and construction applications.Q: When is it time to replace a Sand Shot Blast Hose?

A: Replacement is recommended if you notice visible signs of wear, reduced performance, persistent leaks, or if the hose wall thickness drops below the original specification (614 mm). Regular inspection ensures safe and efficient operation.Q: Where can Sand Shot Blast Hoses be applied?

A: They are widely used in construction sites, shipyards, industrial cleaning facilities, and any setting where intensive sand or shot blasting is required for maintenance, surface treatment, or cleaning tasks.Q: What is the process for selecting the correct hose size and end connection?

A: Determine the required inside and outside diameter based on your blasting equipment, and select the end finisheither plain or flangedcompatible with your system. Consult with the supplier to ensure the hose meets your specific operating pressures and length requirements.Q: What benefits do these hoses offer in industrial operations?

A: With high flexibility, excellent abrasion and weather resistance, as well as good ozone protection, these hoses provide longevity and consistent performance. Their robust construction supports safe operation under high pressures and tough working conditions, minimizing downtime and maintenance needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email