- Home Page

- Company Profile

-

Our Products

- Braided Hose

- Suction & Delivery Hose

- PVC Antistatic Non Toxic Hose

- Lay Flat Delivery Hose (Blue Color)

- HDPE Pipes & Fittings

- PVC Pipe & Fittings

- U-pvc Casing Pipes (Blue Color)

- Threaded Plumbing Pipes

- U-pvc Pipes and Fittings (Grey - Isi-4985)

- Dutron Upvc Pressure Pipes (Grey Is-4985)

- Upvc Casing Pipes

- Upvc Plumbing Pipe (White-ASTM-D-1785)

- Moulded Fittings

- Fabricated Fittings

- Column Pipes

- C-pvc Water Pipes (Hot Water)

- UPVC Column Pipe (Ashirvad Make)

- Polypropylene Pipe & Fittings

- Acrylic / Polycarbonate Pipe

- Corrugated Pipes

- High Temperature Hose (Imported - GERMANY )

- Industrial Valves

- PP Sight Glass Valve Type T11

- NRV Non-Return Valve Type T10

- Diaphragm Valves

- Actuated Valve

- Foot Valve Type T9

- Butterfly Valve

- Ball Valve Suitable For Heavy Concentrated Chemical Type T7

- Ball Valve Flange End Type T1

- Ball Valve Suitable For Salt Water Type T2

- PP Damper Valve

- Ball Valve Screw End Type T1

- Ball Valve Suitable For Chemical Acid Type T3

- Ball Valve (Suitable For Acid High Type T4)

- Ball Valve Suitable For Abrasive Crystal Chemical Type T5

- Ball Valve Suitable For High Abrasive Crystal Chemical For Solvent Type T6

- Ball Valve Suitable For Very High. Cons. Chemical Type T8

- Rubber Hose

- PPR Pipe Fittings(Green Color)

- Plastic Sheets

- DWC PIPE

- PU Spiral Duct Hose

- HDPE Welding Machine

- Pipe Support ( FLOAT )

- Medical Gas Hose

- Welding Machine

- Pipe Floats

- PP Strainer

- Pipeline Installation Services

- Flexible Hose

- HDPE Pipe Fitting

- EF Elbow 90 (Electro Fusion) (Short Bend - 90 Deg.)

- EF Coupler (Electro fusion) (Socket)

- EF Tee (Electro-Fusion) (Equal tee)

- EF Elbow 45 (Electro Fusion)

- EF Tapping Saddle (Electro Fusion) (With Boom)

- EF End Cap ( Electro-Fusion)

- EF Stub End (Electro-Fusion) (Without METAL Flange)

- EF Tapping Tee (Electro-Fusion) (With Bottom)

- EF Transition Coupler (Electro-Fusion)

- Alignment Tool

- Saddle Holder (Support)

- Scrapper Scrapper

- Chamfering Tool

- EF Welding Machine- (Electro-Fusion) (With Printer)

- EF Welding Machine (Electro-Fusion) (Manual Type)

- EF Welding Machine- (Electro-Fusion) AUTOMATIC (Bluetooth Enable)

- EF Welding Machine (Electro-Fusion) AUTOMATIC ( Biuetooth Enable)

- Contact Us

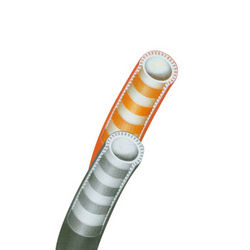

Rock Drill Rubber Hose

Product Details:

- Reinforcement High tensile synthetic textile ply or braided

- Cover Abrasion, weather, and ozone resistant synthetic rubber

- Shape Round

- Hardness 655 Shore A

- Medium Air/Water

- Temperature Up to 70C

- Pressure Up to 20 bar (300 psi)

- Click to View more

X

Rock Drill Rubber Hose Price And Quantity

- 1 Unit

Rock Drill Rubber Hose Product Specifications

- High tensile synthetic textile ply or braided

- Abrasion, weather, and ozone resistant synthetic rubber

- Round

- 12 mm to 50 mm

- Up to 70C

- Appropriate to inside diameter and pressure rating

- 655 Shore A

- Air/Water

- Up to 20 bar (300 psi)

Rock Drill Rubber Hose Trade Information

- Yes

- Free samples are available

- All India

- ISO:9001

Product Description

We have marked a distinguished position in this domain by supplying a comprehensive array of Rock Drill Hoses. Manufactured using quality approved rubber cover with nylon tape in adherence with set industry norms, offered hoses are checked on several quality parameters to ensure their optimal performance. These hoses find their main use for providing fluid pressure at certain places. Also, these Rock Drill Hoses can get from us in varied lengths and thicknesses as per the clients' requirement.

Features:

-

Oil resistance

-

High strength

-

Weather and abrasion resistant

-

Accurate dimension

| Tube | Seamless, smooth, uniform in thickness and has concentric rubber tube, resistant to mist |

| Reinforcement | Textile reinforcement impregnated with rubber in suitable number of plies or braided with high strength synthetic fiber or high tensile steel wire |

| Cover | Black rubber cover with nylon tape finish or plain with weather and abrasion resistant compound |

| Temperature range | -40 °F to +160°F |

| Length | Steel Mendel built hoses upto 18 meters (max) |

Designed for Rugged Industrial Use

Engineered to endure harsh outdoor and heavy-duty work settings, this hose excels in mining, rock drilling, and construction sectors. Its synthetic construction ensures resistance to abrasion, weather, and ozone, delivering long-term durability and safety.

Superior Flexibility and Handling

Enjoy the ease of maneuvering tools and equipment; the highly flexible design guarantees efficient operation. The hose remains smooth and easily manageable, reducing fatigue and simplifying set-up and storage after use.

Customizable to Your Needs

Choose from a range of inside diameters (12 mm to 50 mm) and lengths up to 20 meters, with the option for custom cuts. You can also select the ideal end finishsmooth, with or without coupling, tailored to your applications requirements.

FAQs of Rock Drill Rubber Hose:

Q: How should the Rock Drill Rubber Hose be installed for optimal performance?

A: To achieve optimal performance, the hose should be installed with smooth, gradual bends and should not be twisted or kinked. Secure the hose with appropriate couplings if required, and avoid dragging over sharp surfaces. Ensure the hose is laid out flat during use to prevent unnecessary strain.Q: What are the key benefits of using this hose for mining and construction applications?

A: This hose provides high flexibility, reliability under pressure, and excellent resistance to abrasion and weather. It is leak-proof, conforms to IS: 446/87 standards, and is tailored for the rigorous demands of mining and construction, ensuring both safety and a long service life.Q: When should I choose a custom length for my hose?

A: Select a custom length hose when standard sizes do not meet your workspace or equipment requirements. This ensures a tidy, safe, and efficient work environment without excess slack or unnecessary extensions.Q: Where can this rubber hose be effectively employed?

A: The hose is ideal for outdoor and heavy-duty sites such as rock drilling operations, mining facilities, and construction zones. It is also compatible with pneumatic tools and any application demanding heavy performance in demanding outdoor settings.Q: What is the recommended process for routine maintenance?

A: Regularly inspect the hose for signs of wear, abrasion, or damage. Clean the exterior to remove dirt or chemicals, store in coils or rolls in a dry, shaded area, and avoid prolonged exposure to extreme temperatures or direct sunlight when not in use.Q: How does the hose ensure safety during operation?

A: The hose features a high minimum bursting pressure of 60 bar and a working pressure up to 20 bar, reinforced by high-tensile synthetic ply or braid. It is leak-proof and abrasion-resistant, meeting IS: 446/87 standards for reliable and safe performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email