- Home Page

- Company Profile

-

Our Products

- Braided Hose

- Suction & Delivery Hose

- PVC Antistatic Non Toxic Hose

- Lay Flat Delivery Hose (Blue Color)

- HDPE Pipes & Fittings

- PVC Pipe & Fittings

- U-pvc Casing Pipes (Blue Color)

- Threaded Plumbing Pipes

- U-pvc Pipes and Fittings (Grey - Isi-4985)

- Dutron Upvc Pressure Pipes (Grey Is-4985)

- Upvc Casing Pipes

- Upvc Plumbing Pipe (White-ASTM-D-1785)

- Moulded Fittings

- Fabricated Fittings

- Column Pipes

- C-pvc Water Pipes (Hot Water)

- UPVC Column Pipe (Ashirvad Make)

- Polypropylene Pipe & Fittings

- Acrylic / Polycarbonate Pipe

- Corrugated Pipes

- High Temperature Hose (Imported - GERMANY )

- Industrial Valves

- PP Sight Glass Valve Type T11

- NRV Non-Return Valve Type T10

- Diaphragm Valves

- Actuated Valve

- Foot Valve Type T9

- Butterfly Valve

- Ball Valve Flange End Type T1

- Ball Valve Suitable For Salt Water Type T2

- Ball Valve Suitable For Heavy Concentrated Chemical Type T7

- PP Damper Valve

- Ball Valve Screw End Type T1

- Ball Valve Suitable For Chemical Acid Type T3

- Ball Valve (Suitable For Acid High Type T4)

- Ball Valve Suitable For Abrasive Crystal Chemical Type T5

- Ball Valve Suitable For High Abrasive Crystal Chemical For Solvent Type T6

- Ball Valve Suitable For Very High. Cons. Chemical Type T8

- Rubber Hose

- PPR Pipe Fittings(Green Color)

- Plastic Sheets

- DWC PIPE

- PU Spiral Duct Hose

- Medical Gas Hose

- Welding Machine

- Pipe Floats

- PP Strainer

- Pipeline Installation Services

- Flexible Hose

- HDPE Pipe Fitting

- EF Elbow 90 (Electro Fusion) (Short Bend - 90 Deg.)

- EF Coupler (Electro fusion) (Socket)

- EF Tee (Electro-Fusion) (Equal tee)

- EF Elbow 45 (Electro Fusion)

- EF Tapping Saddle (Electro Fusion) (With Boom)

- EF End Cap ( Electro-Fusion)

- EF Stub End (Electro-Fusion) (Without METAL Flange)

- EF Tapping Tee (Electro-Fusion) (With Bottom)

- EF Transition Coupler (Electro-Fusion)

- Alignment Tool

- Saddle Holder (Support)

- Scrapper Scrapper

- Chamfering Tool

- EF Welding Machine- (Electro-Fusion) (With Printer)

- EF Welding Machine (Electro-Fusion) (Manual Type)

- EF Welding Machine- (Electro-Fusion) AUTOMATIC (Bluetooth Enable)

- EF Welding Machine (Electro-Fusion) AUTOMATIC ( Biuetooth Enable)

- Contact Us

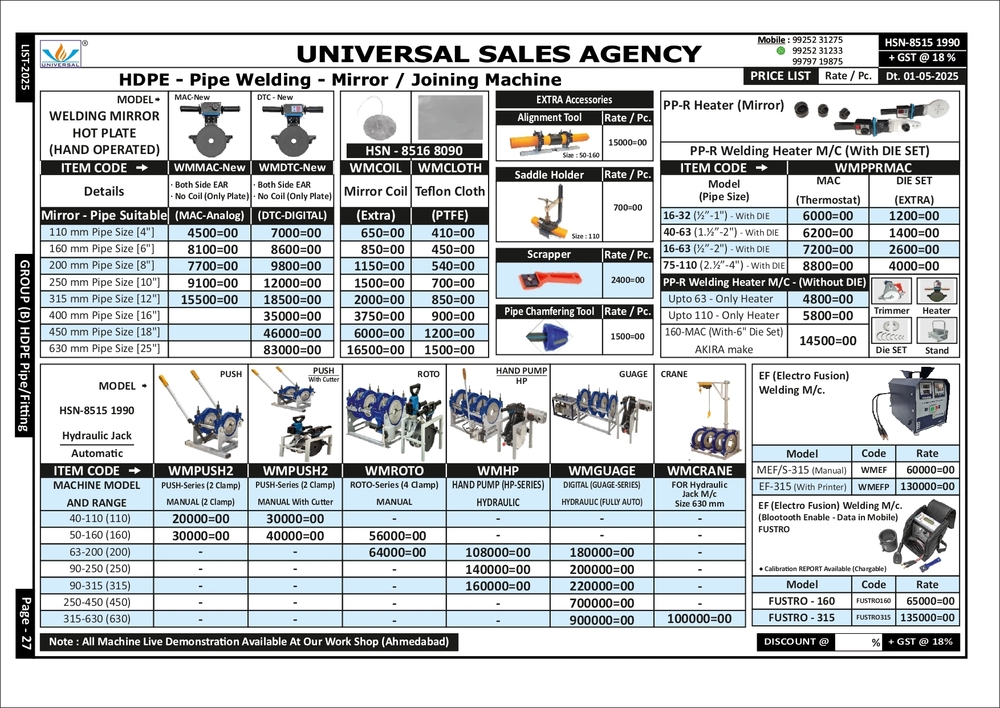

HDPE Pipe Welding Machine Mirror

83000 INR/Piece

Product Details:

- Air Pressure Not Applicable (Electric Heating)

- Automation Semi-Automatic

- Type Butt Fusion Welding Mirror

- Material Aluminum Mirror with Non-stick Coating

- Usage HDPE Pipe Butt Fusion Welding

- Welding Area Up to 315 mm diameter pipes

- Dimension (L*W*H) 450 x 270 x 90 mm

- Click to View more

X

HDPE Pipe Welding Machine Mirror Price And Quantity

- 1 Piece

- 83000 INR/Piece

HDPE Pipe Welding Machine Mirror Product Specifications

- 2.5 kW

- Aluminum Mirror with Non-stick Coating

- 220 V / 230 V

- Up to 315 mm diameter pipes

- 10 kg (approx.)

- Semi-Automatic

- 450 x 270 x 90 mm

- Manual

- Not Applicable (Electric Heating)

- Butt Fusion Welding Mirror

- 50/60 Hz

- HDPE Pipe Butt Fusion Welding

Product Description

Used Forï:-ïHDPE Pipe Joining Methods are Done in 2 Different Ways. HDPE Pipe is Connected By Butt Welding, Electrofusion Welding or Mechanical Fasteners.

Applications & Featuresï:-ïSuitable For But Fusion Welding Of Plastic Pipes & Fittings Made Of PE, PP and PVDF In Construction Site Or Workshop, On/Off Switch Control on Handle (SC) Inbuilt Thermostat Controller With LED Indication. (MAC) PID-SMPS Based Digital Temperature Controller. Inbuilt Countdown Timer With Buzzer Signal. Easy To Replace By Yourself. (DTC) No Handle Breaking Problem Extra Tough High Strength Rigid Handle Design. Super Smooth Teflon Coated Surface (Can Apply Teflon Cloth Layer). Replaceable Mica Plate Heater Coil.

Product Details:-ïHeating Plate/Mirror are All Pressure Die Casted With Teflon Coated For Non Sticking of Any PE Melting Thermostatic Temperature Adjustment And Indicator Light Indicated Temp Adjustment and Maintain the Heating Temp at Set Point. Made up of High Quality Aluminum Metal for Long Life and Easy to Repair.

For price click below link

Reliable Non-Stick Coated Mirror Plate

The aluminum mirror plate is treated with a special non-stick surface coating, minimizing molten plastic adhesion during welding. This ensures quick cleaning and long-term operational efficiency, reducing maintenance time and preserving mirror quality even with frequent use on HDPE, PP, or PVDF pipes.

Efficient Heating and Rapid Warm-Up

Embedded with a spiral heating element, the mirror plate achieves temperatures up to 300C in less than 10 minutes. This rapid warm-up minimizes downtime, allowing operators to begin the welding process quickly and maintain productivity across multiple pipe joints of varying diameters up to 315mm.

Built-In Safety and User-Friendly Operation

Safety is a priority with integrated overheat protection and an ergonomically insulated handle, protecting users from accidental burns. The machine is designed for simple manual control, with a robust 2-meter power cable providing flexible movement during semi-automatic butt fusion welding operations.

FAQs of HDPE Pipe Welding Machine Mirror:

Q: How do I operate the HDPE Pipe Welding Machine Mirror for butt fusion welding?

A: To operate, first connect the device to a 220V/230V power source. Set the desired temperature (up to 300C) using the manual control system. Once the mirror reaches the set temperature, place the prepared pipe ends against the mirror for heating, then proceed with butt fusion as per standard welding procedures. Always utilize the insulated handle for safe handling.Q: What types and sizes of pipes can this welding mirror accommodate?

A: This welding mirror is compatible with HDPE, PP, and PVDF pipe materials, and supports welding pipes with diameters up to 315 mm, making it suitable for various industrial and construction applications.Q: When should I use a non-stick coated welding mirror in pipeline applications?

A: A non-stick coated mirror is ideal when welding thermoplastic pipes where residue build-up from molten materials is a concern. The coated surface allows for easier cleaning, prolongs the mirrors lifespan, and maintains welding quality even during frequent or high-volume use.Q: Where is the HDPE Pipe Welding Machine Mirror commonly used?

A: It is widely used across construction sites, industrial plants, plumbing, and municipal infrastructure projects within India, wherever reliable butt fusion welding of plastic pipes, especially HDPE, PP, or PVDF, is necessary.Q: What are the safety features included in this welding machine mirror?

A: This device is equipped with overheat protection to prevent temperature surges, and features an insulated handle to safeguard against accidental burns, ensuring a safer user experience during pipe welding operations.Q: How does the embedded spiral heater benefit the welding process?

A: The embedded spiral heater distributes heat efficiently and evenly across the mirror plate, ensuring consistent pipe fusion. It enables the machine to reach operational temperature rapidly, reducing waiting time and supporting faster workflow on job sites.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email