- Home Page

- Company Profile

-

Our Products

- Braided Hose

- Suction & Delivery Hose

- PVC Antistatic Non Toxic Hose

- Lay Flat Delivery Hose (Blue Color)

- HDPE Pipes & Fittings

- PVC Pipe & Fittings

- U-pvc Casing Pipes (Blue Color)

- Threaded Plumbing Pipes

- U-pvc Pipes and Fittings (Grey - Isi-4985)

- Dutron Upvc Pressure Pipes (Grey Is-4985)

- Upvc Casing Pipes

- Upvc Plumbing Pipe (White-ASTM-D-1785)

- Moulded Fittings

- Fabricated Fittings

- Column Pipes

- C-pvc Water Pipes (Hot Water)

- UPVC Column Pipe (Ashirvad Make)

- Polypropylene Pipe & Fittings

- Acrylic / Polycarbonate Pipe

- Corrugated Pipes

- High Temperature Hose (Imported - GERMANY )

- Industrial Valves

- PP Sight Glass Valve Type T11

- NRV Non-Return Valve Type T10

- Diaphragm Valves

- Actuated Valve

- Foot Valve Type T9

- Butterfly Valve

- Ball Valve Suitable For Heavy Concentrated Chemical Type T7

- Ball Valve Flange End Type T1

- Ball Valve Suitable For Salt Water Type T2

- PP Damper Valve

- Ball Valve Screw End Type T1

- Ball Valve Suitable For Chemical Acid Type T3

- Ball Valve (Suitable For Acid High Type T4)

- Ball Valve Suitable For Abrasive Crystal Chemical Type T5

- Ball Valve Suitable For High Abrasive Crystal Chemical For Solvent Type T6

- Ball Valve Suitable For Very High. Cons. Chemical Type T8

- Rubber Hose

- PPR Pipe Fittings(Green Color)

- Plastic Sheets

- DWC PIPE

- PU Spiral Duct Hose

- Medical Gas Hose

- Welding Machine

- Pipe Floats

- PP Strainer

- Pipeline Installation Services

- Flexible Hose

- HDPE Pipe Fitting

- EF Elbow 90 (Electro Fusion) (Short Bend - 90 Deg.)

- EF Coupler (Electro fusion) (Socket)

- EF Tee (Electro-Fusion) (Equal tee)

- EF Elbow 45 (Electro Fusion)

- EF Tapping Saddle (Electro Fusion) (With Boom)

- EF End Cap ( Electro-Fusion)

- EF Stub End (Electro-Fusion) (Without METAL Flange)

- EF Tapping Tee (Electro-Fusion) (With Bottom)

- EF Transition Coupler (Electro-Fusion)

- Alignment Tool

- Saddle Holder (Support)

- Scrapper Scrapper

- Chamfering Tool

- EF Welding Machine- (Electro-Fusion) (With Printer)

- EF Welding Machine (Electro-Fusion) (Manual Type)

- EF Welding Machine- (Electro-Fusion) AUTOMATIC (Bluetooth Enable)

- EF Welding Machine (Electro-Fusion) AUTOMATIC ( Biuetooth Enable)

- Contact Us

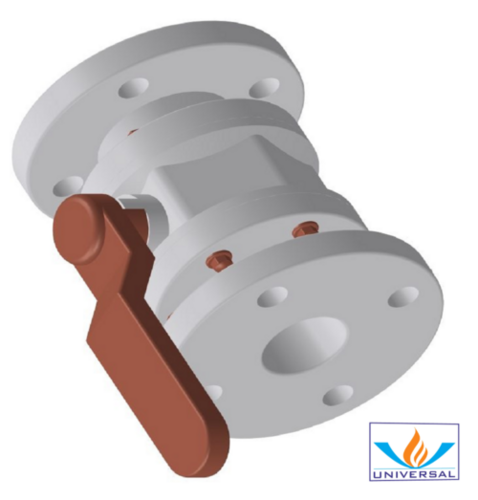

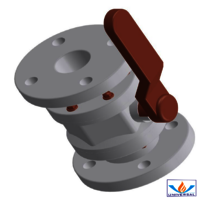

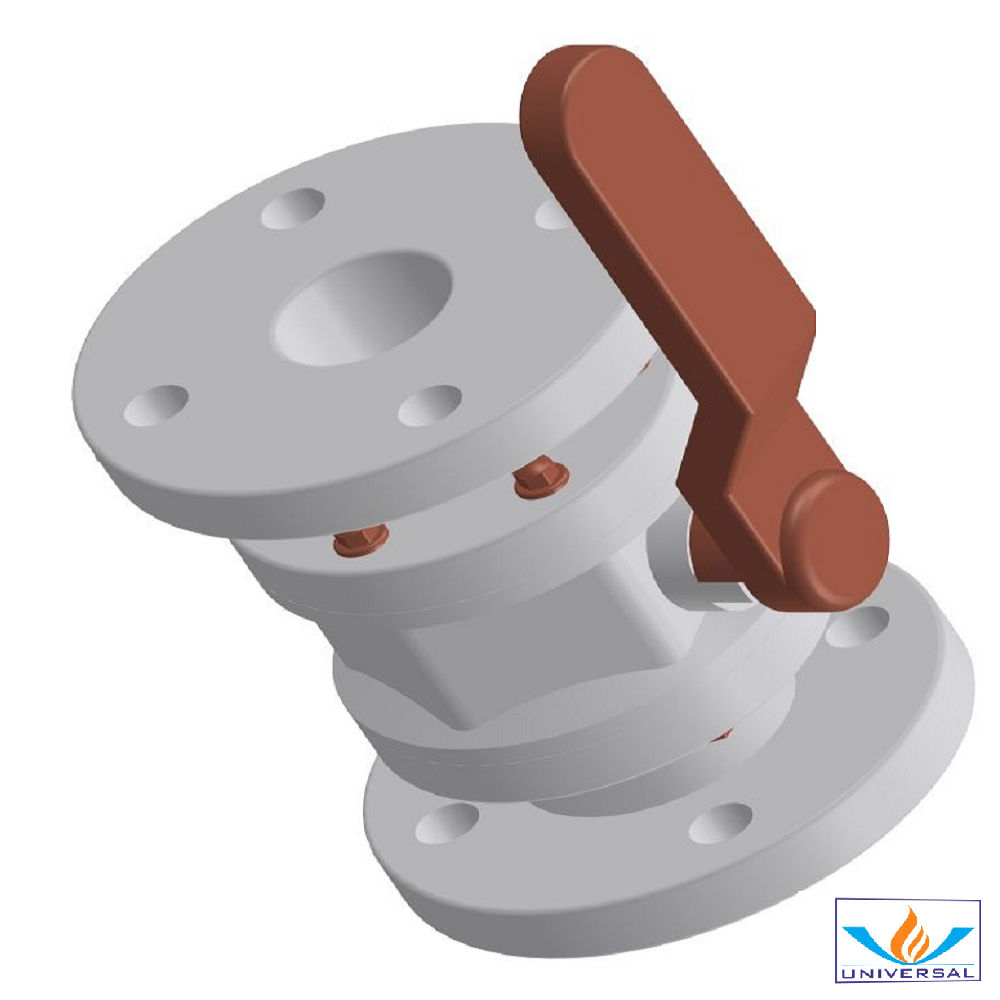

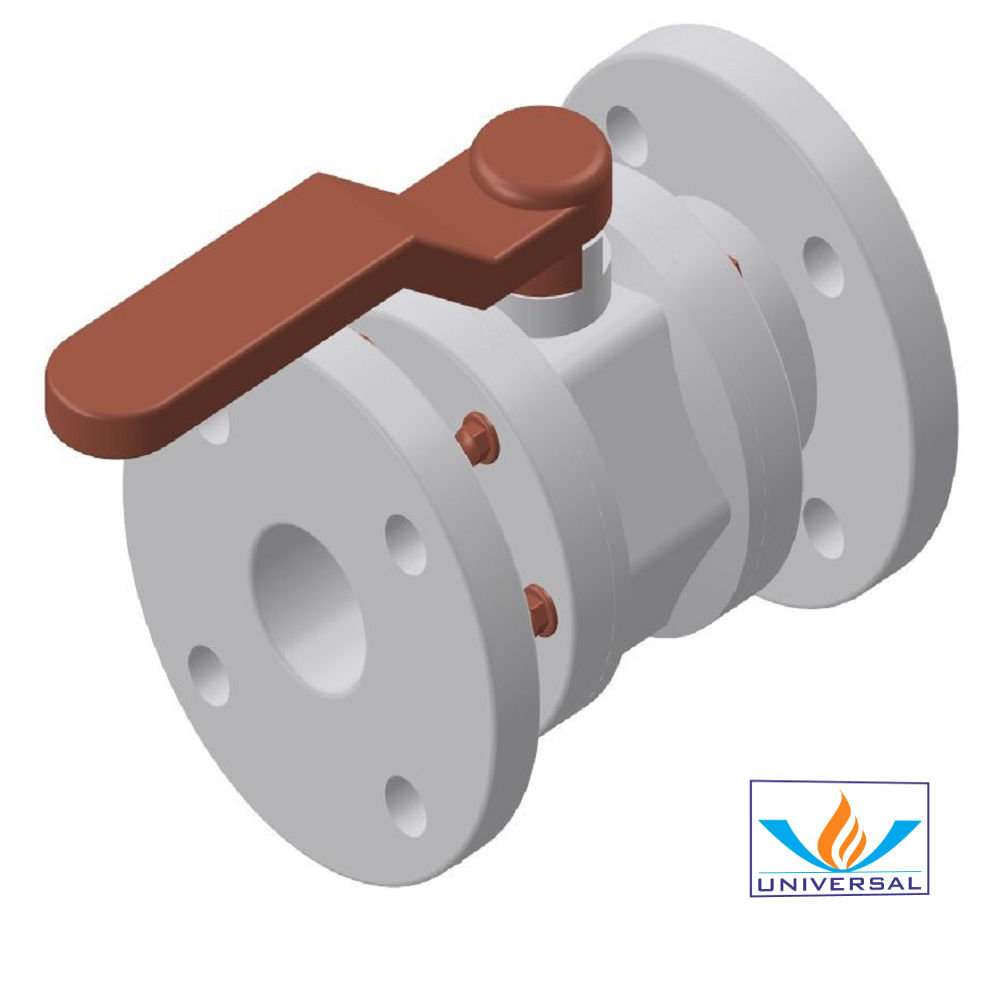

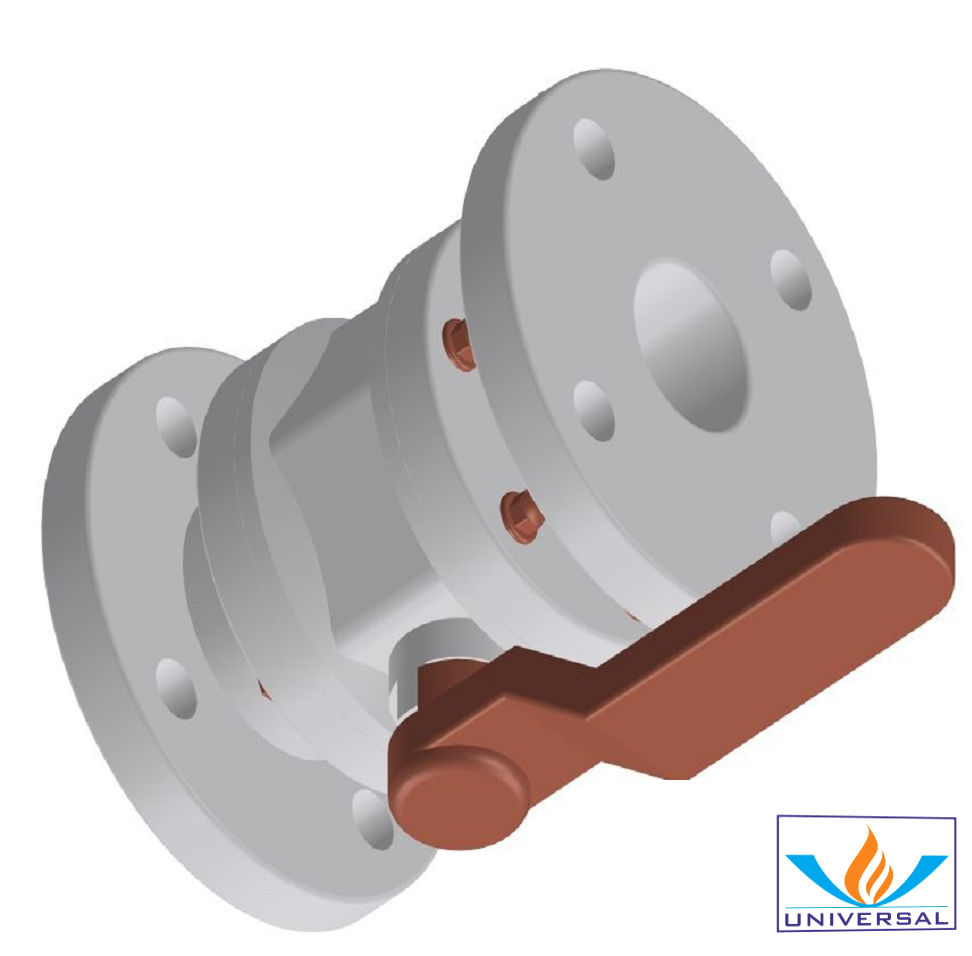

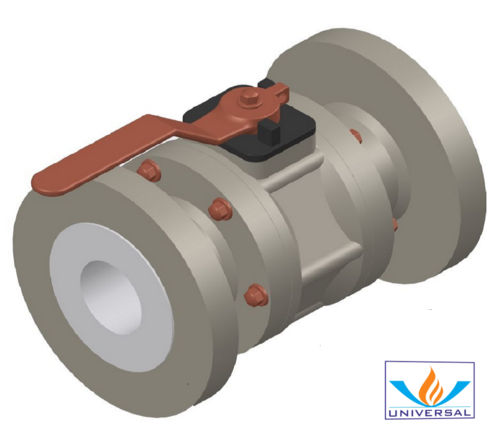

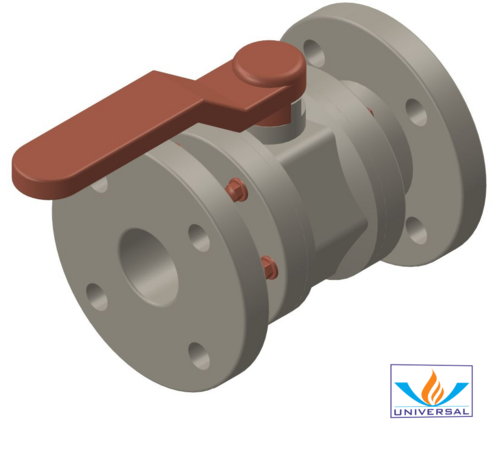

Ball Valve Suitable For Chemical Acid Type T3

1000 INR/Number

Product Details:

- Color Pattern Dual Tone

- Surface Finish Smooth

- Tensile Strength 2535 MPa

- Leak Protection Double O-ring sealing

- Melting Point 160170C

- UV Resistant Yes

- Plastic Type Polypropylene (PP)

- Click to View more

X

Ball Valve Suitable For Chemical Acid Type T3 Price And Quantity

- 10 Number

- 1000 INR/Number

Ball Valve Suitable For Chemical Acid Type T3 Product Specifications

- Dual Tone

- Smooth

- 2535 MPa

- 300-700 Grams

- Yes

- 160170C

- Double O-ring sealing

- Polypropylene (PP)

- Injection Molding

- 15 mm to 50 mm

- Plastic

- White-Green

- Chemical Acid Type T3 Ball Valve

- 0.9 Gram per cubic centimeter(g/cm3)

- Up to 90C

- Compression/Injection

- Rigid

- 4 - 6 Inch

Product Description

P-H isThe Best Thermoplastic For Chemical Uses Resins and Partially Crystalline ResinBelonging to The Engineering Thermoplastic Family of Polyolefins. PPH BallValve is Obtained Through The Polymerization Of Propylene (C3H6) With The AidOf Catalysts.

Standard :- As PerManufacturer Standard

Connection End :-Flangedas per ANSI B 16.5 (150#) & BS 10 (Table D/E/F) & DIN STD.

It has strong chemical resistance, excellentthermal stability, and mechanical resilience, even when subjected to stress. Itis the appropriate material for producing goods such as flanges and freeflanges due to its low specific weight and long-time duration. PPH is alsosuitable for contact with foodstuffs due to its low conductivity and abrasionresistance. Pressure Rating:- Drilling Standards:-

| BODY | 15NB TO 65NB | 10 KG/CM2 (140 PSI) |

|

| 80NB TO 150NB | 8 KG/CM2 (115 PSI) |

| SEAT | 15NB TO 150NB | 10 KG/CM2 (140 PSI) |

Enhanced Chemical and Acid Resistance

Designed specifically for demanding chemical and acid flow control applications, this T3 ball valve utilizes high-grade polypropylene for outstanding corrosion resistance. Its double O-ring sealing ensures superior leak protection, making it ideal for laboratories, process industries, and water treatment plants where reliability is paramount.

Robust and User-Friendly Construction

Manufactured by injection and compression molding, the valve combines a rigid structure with a smooth dual-tone finish. The plastic-coated steel handle provides comfortable manual operation, while threaded end connections allow for easy installation across various systems. With a low-maintenance profile, users experience operational simplicity and longevity.

FAQ's of Ball Valve Suitable For Chemical Acid Type T3:

Q: How does the Chemical Acid Type T3 Ball Valve ensure leak protection during acidic media flow?

A: The valve features double O-ring sealing, which significantly enhances leak prevention and maintains secure operation, especially when handling aggressive acidic or chemical fluids.Q: What materials are used in the construction of this ball valve and why are they suitable for corrosive environments?

A: The valve is made from rigid polypropylene (PP) molded through injection or compression techniques. Polypropylene is highly resistant to acids and chemicals, ensuring durability and minimal corrosion in harsh industrial environments.Q: When should I consider using this ball valve for my flow control requirements?

A: You should consider the Chemical Acid Type T3 Ball Valve for applications requiring safe and efficient control of chemical, acidic, or water media, especially where excellent corrosion resistance and low maintenance are priorities.Q: Where can this ball valve be installed?

A: This valve is suitable for installation in chemical processing plants, laboratories, water treatment facilities, and any setup where control of liquid or acidic flow is necessary, provided the connection sizes (15 mm to 50 mm) are compatible with existing piping.Q: What is the process for installing and maintaining the Chemical Acid Type T3 Ball Valve?

A: Installation involves threading the valve onto compatible pipes using the threaded ends. Maintenance is minimal due to the valve's robust materials and sealing design; periodic inspection for wear is recommended to ensure ongoing leak-free performance.Q: How does the full bore design benefit flow control operations?

A: A full bore design enables unobstructed media passage, resulting in minimal pressure loss and efficient on/off flow control, which is vital for both acidic and neutral liquid applications.Q: What are the benefits of the manual automation grade and plastic-coated steel handle?

A: Manual operation offers direct control over flow, making adjustments straightforward. The plastic-coated steel handle ensures a comfortable grip and resistance to chemical exposure, contributing to safe and convenient usage.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email