- Home Page

- Company Profile

-

Our Products

- Braided Hose

- Suction & Delivery Hose

- PVC Antistatic Non Toxic Hose

- Lay Flat Delivery Hose (Blue Color)

- HDPE Pipes & Fittings

- PVC Pipe & Fittings

- U-pvc Casing Pipes (Blue Color)

- Threaded Plumbing Pipes

- U-pvc Pipes and Fittings (Grey - Isi-4985)

- Dutron Upvc Pressure Pipes (Grey Is-4985)

- Upvc Casing Pipes

- Upvc Plumbing Pipe (White-ASTM-D-1785)

- Moulded Fittings

- Fabricated Fittings

- Column Pipes

- C-pvc Water Pipes (Hot Water)

- UPVC Column Pipe (Ashirvad Make)

- Polypropylene Pipe & Fittings

- Acrylic / Polycarbonate Pipe

- Corrugated Pipes

- High Temperature Hose (Imported - GERMANY )

- Industrial Valves

- PP Sight Glass Valve Type T11

- NRV Non-Return Valve Type T10

- Diaphragm Valves

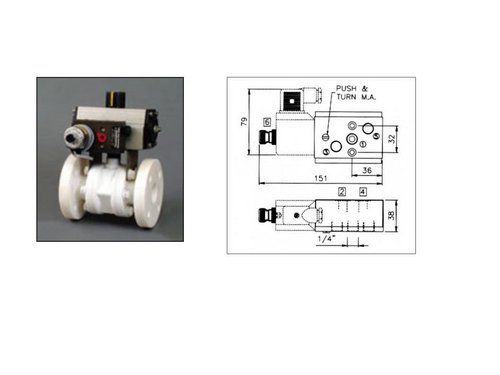

- Actuated Valve

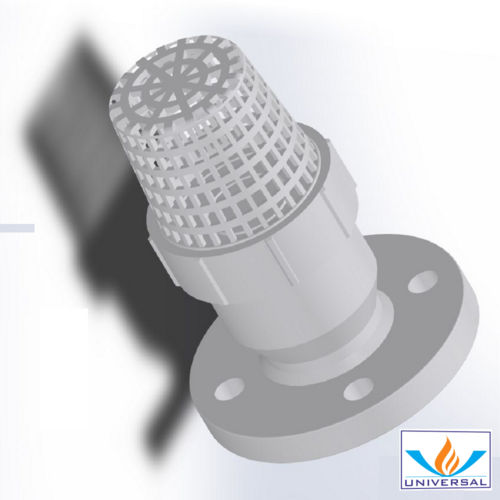

- Foot Valve Type T9

- Butterfly Valve

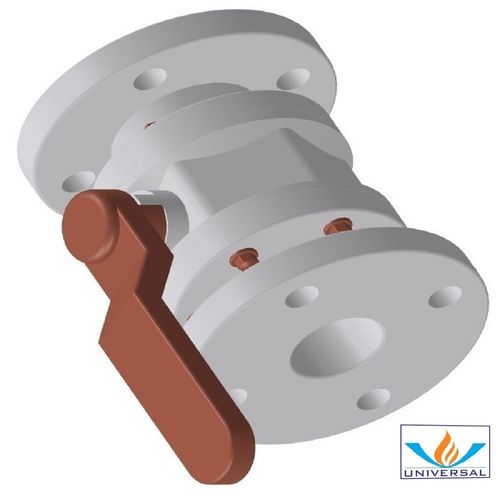

- Ball Valve Flange End Type T1

- Ball Valve Suitable For Salt Water Type T2

- Ball Valve Suitable For Heavy Concentrated Chemical Type T7

- PP Damper Valve

- Ball Valve Screw End Type T1

- Ball Valve Suitable For Chemical Acid Type T3

- Ball Valve (Suitable For Acid High Type T4)

- Ball Valve Suitable For Abrasive Crystal Chemical Type T5

- Ball Valve Suitable For High Abrasive Crystal Chemical For Solvent Type T6

- Ball Valve Suitable For Very High. Cons. Chemical Type T8

- Rubber Hose

- PPR Pipe Fittings(Green Color)

- Plastic Sheets

- DWC PIPE

- PU Spiral Duct Hose

- Medical Gas Hose

- Welding Machine

- Pipe Floats

- PP Strainer

- Pipeline Installation Services

- Flexible Hose

- HDPE Pipe Fitting

- EF Coupler (Electro fusion) (Socket)

- EF Elbow 90 (Electro Fusion) (Short Bend - 90 Deg.)

- EF Tee (Electro-Fusion) (Equal tee)

- EF Elbow 45 (Electro Fusion)

- EF Tapping Saddle (Electro Fusion) (With Boom)

- EF End Cap ( Electro-Fusion)

- EF Stub End (Electro-Fusion) (Without METAL Flange)

- EF Tapping Tee (Electro-Fusion) (With Bottom)

- EF Transition Coupler (Electro-Fusion)

- Alignment Tool

- Saddle Holder (Support)

- Scrapper Scrapper

- Chamfering Tool

- EF Welding Machine- (Electro-Fusion) (With Printer)

- EF Welding Machine (Electro-Fusion) (Manual Type)

- EF Welding Machine- (Electro-Fusion) AUTOMATIC (Bluetooth Enable)

- EF Welding Machine (Electro-Fusion) AUTOMATIC ( Biuetooth Enable)

- Contact Us

Actuated Valve

Product Details:

- UV Resistant Yes

- Density 1.36 Gram per cubic centimeter(g/cm3)

- Heat Resistance Yes

- Color Pattern Solid

- Melting Point Approx. 160C

- Tensile Strength High (typical for industrial grade plastic valves)

- Plastic Type PVC / Polypropylene

- Click to View more

X

Actuated Valve Product Specifications

- Various sizes available

- Injection Molding

- Lightweight

- Approx. 160C

- Thermoplastic

- Standard/Customizable

- Solid

- PVC / Polypropylene

- Black

- Actuated Valve

- Smooth

- High

- High (typical for industrial grade plastic valves)

- Yes

- Plastic

- Yes

- 1.36 Gram per cubic centimeter(g/cm3)

- Flanged / Threaded Connection

- Compatible with water, acids, alkalis & other chemicals

- Excellent

- Electric or Pneumatic

- Socket / Spigot / Flanged

- Water Supply, Chemical Handling, Irrigation, Industrial Automation

- Electric / Pneumatic Actuation Available

- Over 100,000 cycles

- PN10 / PN16

- 24V / 110V / 220V

- EPDM / FPM

- ISO 5211 / CE Certified

Product Description

Actuated Valve

Our company is a prominent supplier of Actuated Valvethat is highly acclaimed by our clients due to its accurate dimension. This valve is efficiently manufactured at our well advanced production unit by making use of optimum quality raw material and hi-tech methodology. The offered valve is used to connect with plumbing system for controlling water flow. We offer an extensive collection of Actuated Valve in various dimensions, shapes and finishes at affordable prices to our patrons.

Features

-

Bi functional version

-

High flow rate, kv=12(lpm@1bar), Fast response time

-

Minimum operating pressure required

-

Suitable for air, gases water etc.

-

Ideally suited for double acting actuator on ON/OFF & control duty

-

Special versions may be developed on request

-

Poppet Design

-

Accessories for mounting the solenoid valve on the actuator are provided.

-

Solenoid of any voltage rating/construction can be replaced at customers end

-

External pilot air operated available

Advanced Actuation and Reliable Performance

Choose from electric or pneumatic actuation to suit your systems control needs. Featuring a robust construction and high-grade thermoplastic materials, this valve delivers precise operation under demanding conditions. Its long cycle life and high tensile strength guarantee dependable performance in various media, from water to harsh chemicals.

Versatile Mounting and Connection

Designed for easy integration, the valve comes with flanged, threaded, socket, and spigot connections. Standard and customizable lengths are available, allowing seamless installation across water supply, chemical handling, irrigation, and industrial applications. Its lightweight build enables simple handling and mounting.

Engineered for Durability and Compliance

Compliant with ISO 5211 and CE directives, this valve is built to last, offering exceptional resistance to corrosion, UV rays, and heat up to 80C. The seamless, smooth surface finish and solid color pattern maintain reliability and appearance even in challenging environments.

FAQs of Actuated Valve:

Q: How is the actuated valve typically installed in an industrial automation setup?

A: The valve is designed with versatile end connectionsflanged, threaded, socket, or spigotmaking installation straightforward. It can be mounted using standard ISO 5211 patterns and is compatible with most pipeline systems. The lightweight construction further simplifies the mounting process.Q: What benefits does the actuator offer over manual valves in industrial settings?

A: Automated actuation enables remote operation, offering greater process control, efficiency, and safety. The valve is rated for over 100,000 cycles, ensuring reliable performance with minimal need for manual intervention, making it ideal for continuous industrial or water supply operations.Q: When should I use electric actuation versus pneumatic actuation for this valve?

A: Electric actuation is best suited for installations with available power (24V, 110V, 220V) and precise position control requirements. Pneumatic actuation is preferred in areas with compressed air infrastructure or where rapid cycling is needed. Both options provide reliable automation depending on workflow priorities.Q: Where can this actuated valve be effectively used?

A: Its chemical-resistant thermoplastic body and high-grade seals make it suitable for water supply, chemical handling, irrigation systems, and industrial automation environments, particularly where exposure to corrosive substances or UV light is a concern.Q: What process ensures the valves corrosion resistance and cycle longevity?

A: Manufactured using injection-molded thermoplastics such as PVC and polypropylene, the valve features EPDM or FPM seals and a smooth surface finish. These materials and construction methods grant the valve excellent corrosion resistance, high cycle life, and heat endurance up to 80C.Q: How do I ensure compatibility with various chemicals and fluids?

A: The valves EPDM/FPM seals and plastic construction offer excellent resistance to water, acids, alkalis, and other chemicals. Always verify compatibility with your specific media and operating conditions to optimize lifespan and reliability.Q: What compliance standards and certifications does the valve meet?

A: This actuated valve conforms to ISO 5211 mounting standards and holds a CE certification, ensuring it meets global quality, safety, and performance benchmarks for automated valve solutions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email