- Home Page

- Company Profile

-

Our Products

- Braided Hose

- Suction & Delivery Hose

- PVC Antistatic Non Toxic Hose

- Lay Flat Delivery Hose (Blue Color)

- HDPE Pipes & Fittings

- PVC Pipe & Fittings

- U-pvc Casing Pipes (Blue Color)

- Threaded Plumbing Pipes

- U-pvc Pipes and Fittings (Grey - Isi-4985)

- Dutron Upvc Pressure Pipes (Grey Is-4985)

- Upvc Casing Pipes

- Upvc Plumbing Pipe (White-ASTM-D-1785)

- Moulded Fittings

- Fabricated Fittings

- Column Pipes

- C-pvc Water Pipes (Hot Water)

- UPVC Column Pipe (Ashirvad Make)

- Polypropylene Pipe & Fittings

- Acrylic / Polycarbonate Pipe

- Corrugated Pipes

- High Temperature Hose (Imported - GERMANY )

- Industrial Valves

- PP Sight Glass Valve Type T11

- NRV Non-Return Valve Type T10

- Diaphragm Valves

- Actuated Valve

- Foot Valve Type T9

- Butterfly Valve

- Ball Valve Suitable For Salt Water Type T2

- Ball Valve Flange End Type T1

- Ball Valve Suitable For Heavy Concentrated Chemical Type T7

- PP Damper Valve

- Ball Valve Screw End Type T1

- Ball Valve Suitable For Chemical Acid Type T3

- Ball Valve (Suitable For Acid High Type T4)

- Ball Valve Suitable For Abrasive Crystal Chemical Type T5

- Ball Valve Suitable For High Abrasive Crystal Chemical For Solvent Type T6

- Ball Valve Suitable For Very High. Cons. Chemical Type T8

- Rubber Hose

- PPR Pipe Fittings(Green Color)

- Plastic Sheets

- DWC PIPE

- PU Spiral Duct Hose

- HDPE Welding Machine

- Pipe Support ( FLOAT )

- Medical Gas Hose

- Welding Machine

- Pipe Floats

- PP Strainer

- Pipeline Installation Services

- Flexible Hose

- HDPE Pipe Fitting

- EF Elbow 90 (Electro Fusion) (Short Bend - 90 Deg.)

- EF Coupler (Electro fusion) (Socket)

- EF Tee (Electro-Fusion) (Equal tee)

- EF Elbow 45 (Electro Fusion)

- EF Tapping Saddle (Electro Fusion) (With Boom)

- EF End Cap ( Electro-Fusion)

- EF Stub End (Electro-Fusion) (Without METAL Flange)

- EF Tapping Tee (Electro-Fusion) (With Bottom)

- EF Transition Coupler (Electro-Fusion)

- Alignment Tool

- Saddle Holder (Support)

- Scrapper Scrapper

- Chamfering Tool

- EF Welding Machine- (Electro-Fusion) (With Printer)

- EF Welding Machine (Electro-Fusion) (Manual Type)

- EF Welding Machine- (Electro-Fusion) AUTOMATIC (Bluetooth Enable)

- EF Welding Machine (Electro-Fusion) AUTOMATIC ( Biuetooth Enable)

- Contact Us

Rubber Carbon Free Hoses

Product Details:

- Shape Round

- Cover Smooth, Green, Abrasion and Weather Resistant Rubber

- Connection Type Plain / Flanged

- Hardness 60 5 Shore A

- Reinforcement High Tensile Synthetic Textile Plies

- Material Rubber (Carbon Free)

- Pressure Up to 10 Bar

- Click to View more

X

Rubber Carbon Free Hoses Price And Quantity

- 1 Unit

- > 1 Mega Ohm

- Green / Black

- Minimum 3 times working pressure

- Up to 15 meters continuous

- High

- IS 444/Type 3A standard

Rubber Carbon Free Hoses Product Specifications

- Smooth, Green, Abrasion and Weather Resistant Rubber

- 22 mm to 118 mm

- 12 mm to 100 mm

- Round

- Rubber (Carbon Free)

- Plain / Flanged

- 60 5 Shore A

- High Tensile Synthetic Textile Plies

- Up to 10 Bar

- > 1 Mega Ohm

- Green / Black

- Minimum 3 times working pressure

- Up to 15 meters continuous

- High

- IS 444/Type 3A standard

Rubber Carbon Free Hoses Trade Information

- Yes

- Free samples are available

- All India

- ISO:9001

Product Description

We are one of the most trusted names in this domain, engrossed in supplying an extensive variety of Heat Resistant Carbon Free Hoses. Offered hoses are manufactured with the aid of modern machines by utilizing superior quality raw materials and latest techniques in compliance with predefined industry terms. These hoses are appreciated for their non-conducive synthetic rubber exterior, which is resistant to oil, heat & electricity. Find their uses in steel mills, oil plants and other engineering industries, we provide these Heat Resistant Carbon Free Hoses in varied lengths and thicknesses at pocket friendly rates.

Features:

-

Excellent elasticity

-

Easy usage

-

Good tolerance capacity

-

Non porous

Heat Resistant Carbon Free Hoses:

Our assorted range of Heat Resistant Carbon Free Hose is appreciated for its non-conducive synthetic rubber exterior, which is resistant to oil, heat & electricity. These are applied in various areas such as steel mills, oil plants and other engineering industries. Clients can avail from us 3 types of following hose :

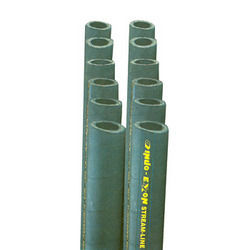

1. Carbon Free Hose

These are used to cover power cables in steel mills, glass work and other, as these are non-conductive (electric) hoses. These avert damage and loss of electric current in power cables, when exposed to open flame splashes or hot metal during radiation.

2. Cable Coolant Hose Plain Or Asbestos Cover

These cover power cables for additional protection, when exposed to extreme temperature, radiation from steel furnace, open flames and others.

3. Furnace Coolant Asbestos Covered Hose

These are heat resistant and suitable in areas like steel mills, glass works, electrical furnaces and more. These protect the cables when exposed for heat radiation, splashes of hot metal and open flames.

Following are the specification of our range:

| Tube | White/black, smooth non-conductive synthetic rubber compound, oil & electrical resistant |

| Reinforcement | Textile infused with rubber in suitable numbers of plies or synthetic fiber yarn |

| Cover | Oil & heat, electrical resistant synthetic rubber compound, white non-conductive (electrical) rubber with asbestos cloth capable of withstanding temperature upto 500C (932F) |

| Temperature | -40F to +200F |

| Length | Max. 18 meters |

Superior Electrical Resistance

These hoses possess electrical resistance greater than 1 Mega Ohm, making them suitable for applications where electrical conductivity must be avoided. Their design ensures safe operation in environments with stringent electrical insulation requirements.

Exceptional Durability and Flexibility

Manufactured from carbon free rubber and reinforced with high tensile synthetic textile plies, the hoses offer a highly flexible yet robust solution. They maintain flexibility across the full length (up to 15 meters continuous) without compromising strength or integrity.

Compliance with IS 444/Type 3A Standards

Each hose is engineered to meet or exceed IS 444/Type 3A standards. This guarantees consistent performance, safety, and reliability for industrial applications, assuring customers of quality and regulatory compliance every time.

FAQs of Rubber Carbon Free Hoses:

Q: How are Rubber Carbon Free Hoses typically used in industrial applications?

A: Rubber Carbon Free Hoses are commonly utilized for conveying water, compressed air, and non-corrosive fluids in environments where high flexibility and electrical insulation are required, such as electrical workshops, power plants, and factories.Q: What benefits do these hoses offer over standard rubber hoses?

A: The major benefits include high electrical resistance (over 1 Mega Ohm), superior flexibility, enhanced durability due to abrasion- and weather-resistant cover, and compliance with international IS 444/Type 3A standards, making them safer and more reliable in critical applications.Q: When should you choose a carbon free hose instead of a conventional rubber hose?

A: A carbon free hose should be chosen if your application involves equipment or environments where electrical conductivity through the hose could pose a hazard, or where enhanced flexibility and mechanical strength are desired.Q: Where can these hoses be installed effectively?

A: These hoses can be installed in areas requiring long, continuous hose runs up to 15 meterssuch as power stations, transformer workshops, industrial plants, laboratories, and any site needing electrical safety and robust fluid transfer capabilities.Q: What is the process for connecting these hoses to existing equipment?

A: The hoses are available with plain or flanged ends, enabling versatile connections. Installation typically involves attaching suitable clamps or flanges that fit the applications specific requirements, ensuring a secure and leak-proof operation.Q: How does the burst pressure compare to the working pressure of these hoses?

A: These hoses provide a safety margin as their bursting pressure is at least three times the specified working pressure, offering enhanced security during operation and reducing the risk of hose failure under sudden pressure surges.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email