- Home Page

- Company Profile

-

Our Products

- Braided Hose

- Suction & Delivery Hose

- PVC Antistatic Non Toxic Hose

- Lay Flat Delivery Hose (Blue Color)

- HDPE Pipes & Fittings

- PVC Pipe & Fittings

- U-pvc Casing Pipes (Blue Color)

- Threaded Plumbing Pipes

- U-pvc Pipes and Fittings (Grey - Isi-4985)

- Dutron Upvc Pressure Pipes (Grey Is-4985)

- Upvc Casing Pipes

- Upvc Plumbing Pipe (White-ASTM-D-1785)

- Moulded Fittings

- Fabricated Fittings

- Column Pipes

- C-pvc Water Pipes (Hot Water)

- UPVC Column Pipe (Ashirvad Make)

- Polypropylene Pipe & Fittings

- Acrylic / Polycarbonate Pipe

- Corrugated Pipes

- High Temperature Hose (Imported - GERMANY )

- Industrial Valves

- PP Sight Glass Valve Type T11

- Actuated Valve

- Ball Valve Suitable For Salt Water Type T2

- Ball Valve Flange End Type T1

- Ball Valve Suitable For Heavy Concentrated Chemical Type T7

- NRV Non-Return Valve Type T10

- Diaphragm Valves

- Foot Valve Type T9

- Butterfly Valve

- PP Damper Valve

- Ball Valve Screw End Type T1

- Ball Valve Suitable For Chemical Acid Type T3

- Ball Valve (Suitable For Acid High Type T4)

- Ball Valve Suitable For Abrasive Crystal Chemical Type T5

- Ball Valve Suitable For High Abrasive Crystal Chemical For Solvent Type T6

- Ball Valve Suitable For Very High. Cons. Chemical Type T8

- Rubber Hose

- PPR Pipe Fittings(Green Color)

- Plastic Sheets

- DWC PIPE

- PU Spiral Duct Hose

- HDPE Welding Machine

- Pipe Support ( FLOAT )

- Medical Gas Hose

- Welding Machine

- Pipe Floats

- PP Strainer

- Pipeline Installation Services

- Flexible Hose

- HDPE Pipe Fitting

- EF Elbow 90° (Electro Fusion) (Short Bend - 90 Deg.)

- EF Coupler (Electro fusion) (Socket)

- EF Tee (Electro-Fusion) (Equal tee)

- EF Elbow 45° (Electro Fusion)

- EF Tapping Saddle (Electro Fusion) (With Boom)

- EF End Cap ( Electro-Fusion)

- EF Stub End (Electro-Fusion) (Without METAL Flange)

- EF Tapping Tee (Electro-Fusion) (With Bottom)

- EF Transition Coupler (Electro-Fusion)

- Alignment Tool

- Saddle Holder (Support)

- Scrapper Scrapper

- Chamfering Tool

- EF Welding Machine- (Electro-Fusion) (With Printer)

- EF Welding Machine (Electro-Fusion) (Manual Type)

- EF Welding Machine- (Electro-Fusion) AUTOMATIC (Bluetooth Enable)

- EF Welding Machine (Electro-Fusion) AUTOMATIC ( Biuetooth Enable)

- Contact Us

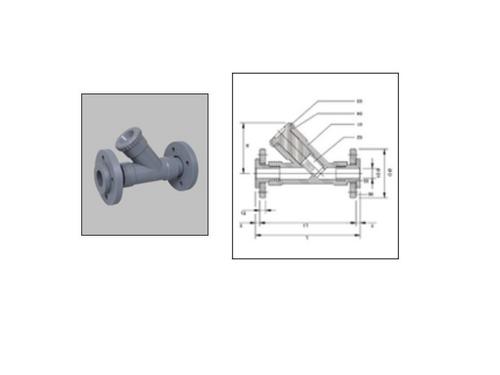

PP Basket Strainer

1000 INR/Number

Product Details:

- Density 0.91 Gram per cubic centimeter(g/cm3)

- Leak Protection Integrated Gasket Sealing

- UV Resistant Yes

- Tensile Strength 35 MPa

- Color Pattern Single Color

- Heat Resistance Up to 90°C

- Plastic Type Virgin Polypropylene

- Click to View more

X

PP Basket Strainer Price And Quantity

- 1000 INR/Number

- As Per Requirement Number

PP Basket Strainer Product Specifications

- Up to 90°C

- Virgin Polypropylene

- Smooth, Matt Finish

- Approx. 150 mm

- Shore D 70-75

- Single Color

- 160-170°C

- Polypropylene (PP)

- White

- Integrated Gasket Sealing

- 0.91 Gram per cubic centimeter(g/cm3)

- Standard (Customized Available)

- Basket Strainer

- Approx. 350 g

- 35 MPa

- Injection Molding

- Yes

- Molded

Product Description

A PP basket strainer is a type of industrial strainer used for filtration of fluids. It is made of polypropylene (PP), a thermoplastic polymer that is resistant to a wide range of chemicals and solvents.

The PP basket strainer typically consists of a basket or mesh filter element housed in a polypropylene body. The basket or mesh filter element is designed to trap larger solid particles and debris, preventing them from flowing downstream and causing damage to pumps, valves, and other equipment.

PP basket strainers are commonly used in industrial applications such as water treatment, chemical processing, and food and beverage processing. They are particularly well-suited for applications where chemical resistance and corrosion resistance are important.

PP basket strainers are available in a range of sizes and configurations, including inline and side-entry designs. They are typically easy to install and maintain, and can be cleaned and reused multiple times before replacement is required.

Overall, PP basket strainers are an effective and reliable solution for fluid filtration in a variety of industrial applications.

Versatile Filtration for Industrial and Agricultural Needs

Engineered from high-grade virgin polypropylene, the PP Basket Strainer offers superior resistance to chemicals, UV degradation, and corrosion, making it ideal for diverse industries including water treatment, chemical processing, and agriculture. Its perforated basket assures a high dirt holding capacity, maintaining optimal flow rates and reducing maintenance frequency.

Reliable Performance Under Pressure

With an operating pressure rating of up to 5 kg/cm2 and an integrated leak-proof gasket, this strainer ensures reliable operation in demanding environments. Its molded design and Shore D hardness of 70-75 provide structural integrity and longevity even under continuous use.

FAQ's of PP Basket Strainer:

Q: How do I install the PP Basket Strainer with flanged or threaded connections?

A: The PP Basket Strainer can be installed using either flanged or threaded end connections, depending on your pipeline system. Simply align the strainer's inlet and outlet horizontally with your pipework and secure the connections. Always ensure proper gasket alignment for leak protection before completing the installation.Q: What types of fluids and industries is this strainer suitable for?

A: This strainer is apt for chemical, water, process, and agricultural applications due to its excellent chemical resistance and high dirt holding capacity. It filters particulates efficiently in systems where corrosion resistance is essential, including industrial and irrigation settings.Q: When should I clean or replace the basket in the strainer?

A: Regularly inspect the strainer based on your system's particulate load and flow rate. The easy-to-remove basket enables quick cleaning whenever blockage or flow reduction is observed. Replacement may be considered if wear, damage, or clogging persists after maintenance.Q: Where can I request customized sizes or alternative configurations?

A: Customized sizes and configurations are available directly from the supplier in India. Contact your local distributor or the manufacturer to specify non-standard dimensions or requirements suited to your installation.Q: What benefits does polypropylene construction provide for this strainer?

A: Polypropylene construction imparts lightweight durability, outstanding corrosion and chemical resistance, UV protection, and suitability for temperatures up to 90C. These features ensure long service life and minimal maintenance even in harsh or corrosive environments.Q: How does the integrated gasket sealing enhance leak protection?

A: The integrated gasket is designed to ensure a tight and reliable seal between the strainer and pipeline, minimizing the risk of leaks even at operating pressures up to 5 kg/cm2. This design reduces the need for additional sealing materials and improves overall system safety.Q: What is the process for routine maintenance of the strainer?

A: Routine maintenance involves shutting off system flow, unscrewing or unbolting the top cover, removing the perforated basket, and cleaning it with water or appropriate solvents. After cleaning, reassemble the unit carefully, ensuring the gasket is correctly seated to maintain leak protection.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email