- Home Page

- Company Profile

-

Our Products

- Braided Hose

- Suction & Delivery Hose

- PVC Antistatic Non Toxic Hose

- Lay Flat Delivery Hose (Blue Color)

- HDPE Pipes & Fittings

- PVC Pipe & Fittings

- U-pvc Casing Pipes (Blue Color)

- Threaded Plumbing Pipes

- U-pvc Pipes and Fittings (Grey - Isi-4985)

- Dutron Upvc Pressure Pipes (Grey Is-4985)

- Upvc Casing Pipes

- Upvc Plumbing Pipe (White-ASTM-D-1785)

- Moulded Fittings

- Fabricated Fittings

- Column Pipes

- C-pvc Water Pipes (Hot Water)

- UPVC Column Pipe (Ashirvad Make)

- Polypropylene Pipe & Fittings

- Acrylic / Polycarbonate Pipe

- Corrugated Pipes

- High Temperature Hose (Imported - GERMANY )

- Industrial Valves

- PP Sight Glass Valve Type T11

- NRV Non-Return Valve Type T10

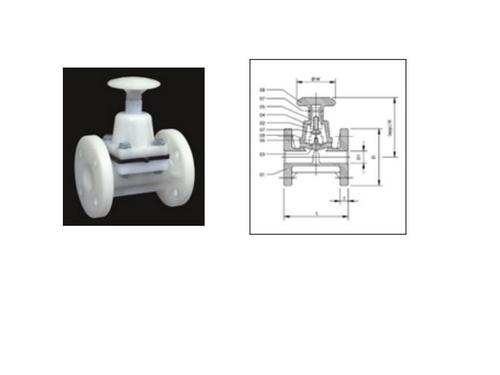

- Diaphragm Valves

- Actuated Valve

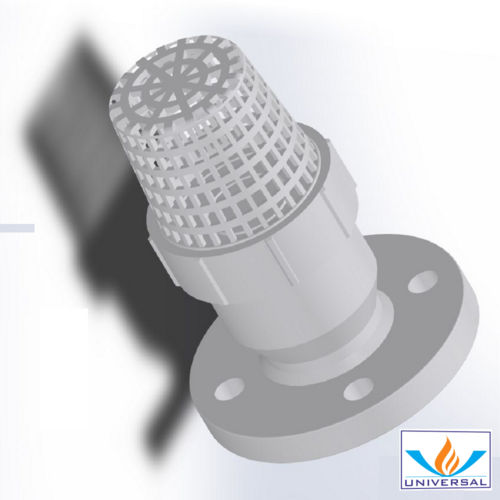

- Foot Valve Type T9

- Butterfly Valve

- Ball Valve Suitable For Heavy Concentrated Chemical Type T7

- Ball Valve Flange End Type T1

- Ball Valve Suitable For Salt Water Type T2

- PP Damper Valve

- Ball Valve Screw End Type T1

- Ball Valve Suitable For Chemical Acid Type T3

- Ball Valve (Suitable For Acid High Type T4)

- Ball Valve Suitable For Abrasive Crystal Chemical Type T5

- Ball Valve Suitable For High Abrasive Crystal Chemical For Solvent Type T6

- Ball Valve Suitable For Very High. Cons. Chemical Type T8

- Rubber Hose

- PPR Pipe Fittings(Green Color)

- Plastic Sheets

- DWC PIPE

- PU Spiral Duct Hose

- Medical Gas Hose

- Welding Machine

- Pipe Floats

- PP Strainer

- Pipeline Installation Services

- Flexible Hose

- HDPE Pipe Fitting

- EF Elbow 90 (Electro Fusion) (Short Bend - 90 Deg.)

- EF Coupler (Electro fusion) (Socket)

- EF Tee (Electro-Fusion) (Equal tee)

- EF Elbow 45 (Electro Fusion)

- EF Tapping Saddle (Electro Fusion) (With Boom)

- EF End Cap ( Electro-Fusion)

- EF Stub End (Electro-Fusion) (Without METAL Flange)

- EF Tapping Tee (Electro-Fusion) (With Bottom)

- EF Transition Coupler (Electro-Fusion)

- Alignment Tool

- Saddle Holder (Support)

- Scrapper Scrapper

- Chamfering Tool

- EF Welding Machine- (Electro-Fusion) (With Printer)

- EF Welding Machine (Electro-Fusion) (Manual Type)

- EF Welding Machine- (Electro-Fusion) AUTOMATIC (Bluetooth Enable)

- EF Welding Machine (Electro-Fusion) AUTOMATIC ( Biuetooth Enable)

- Contact Us

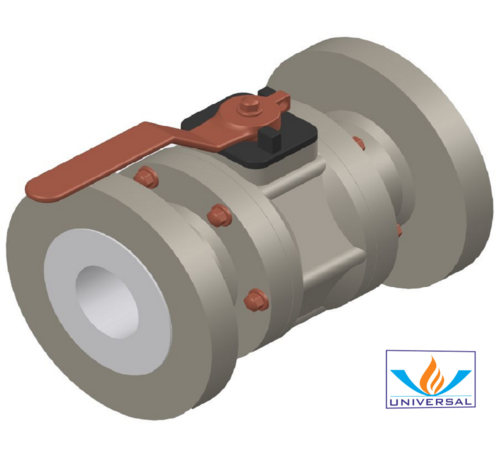

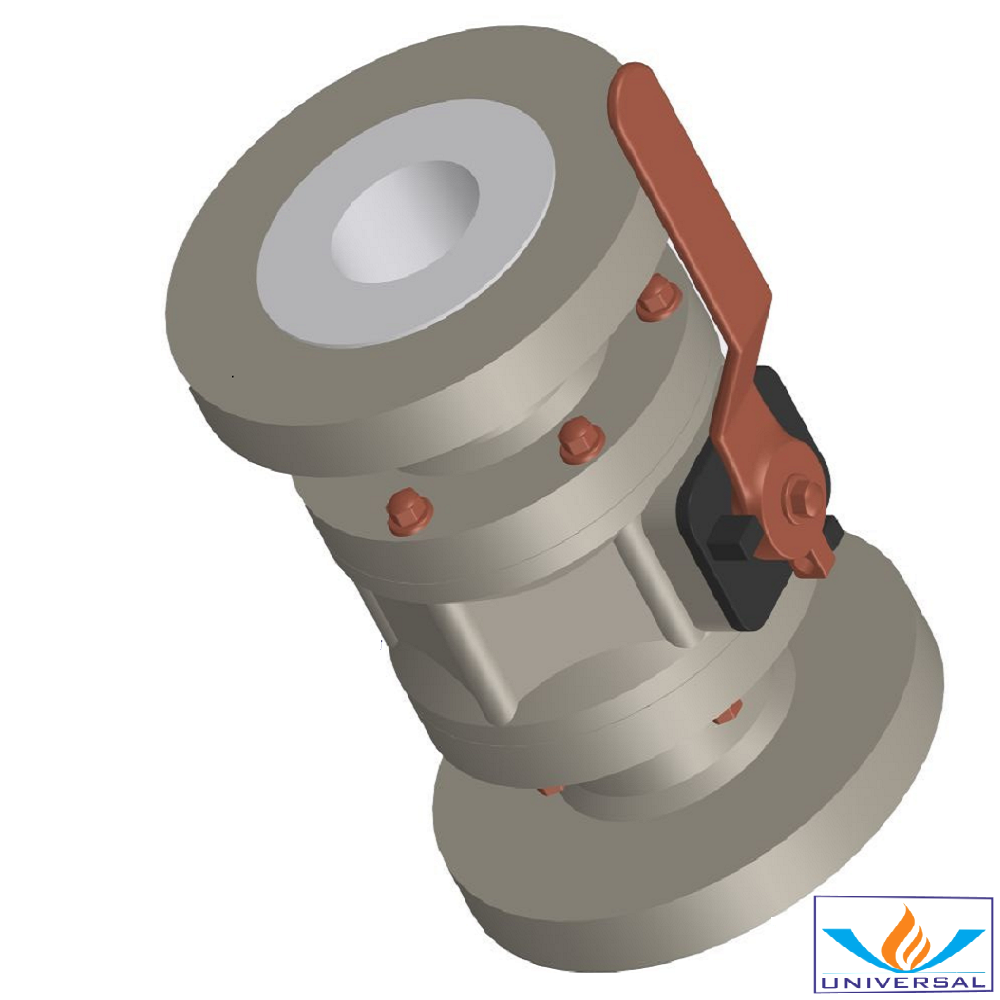

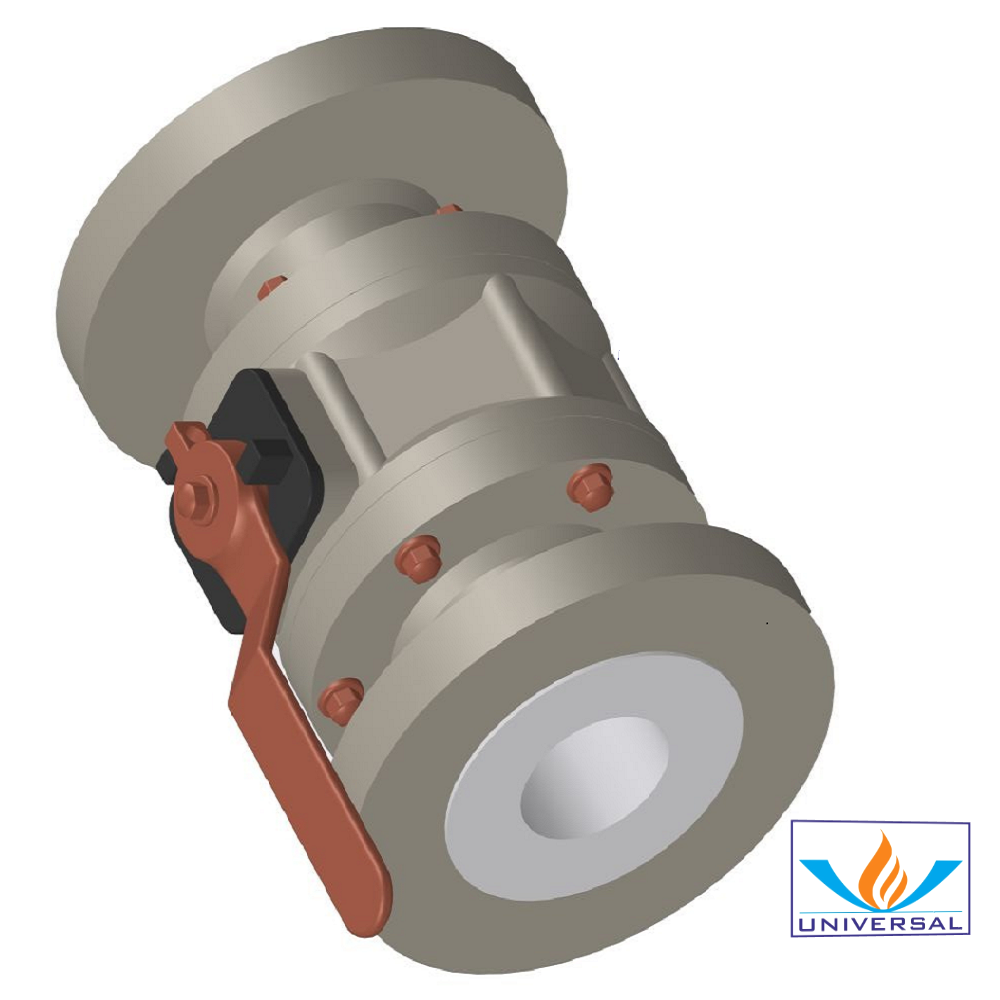

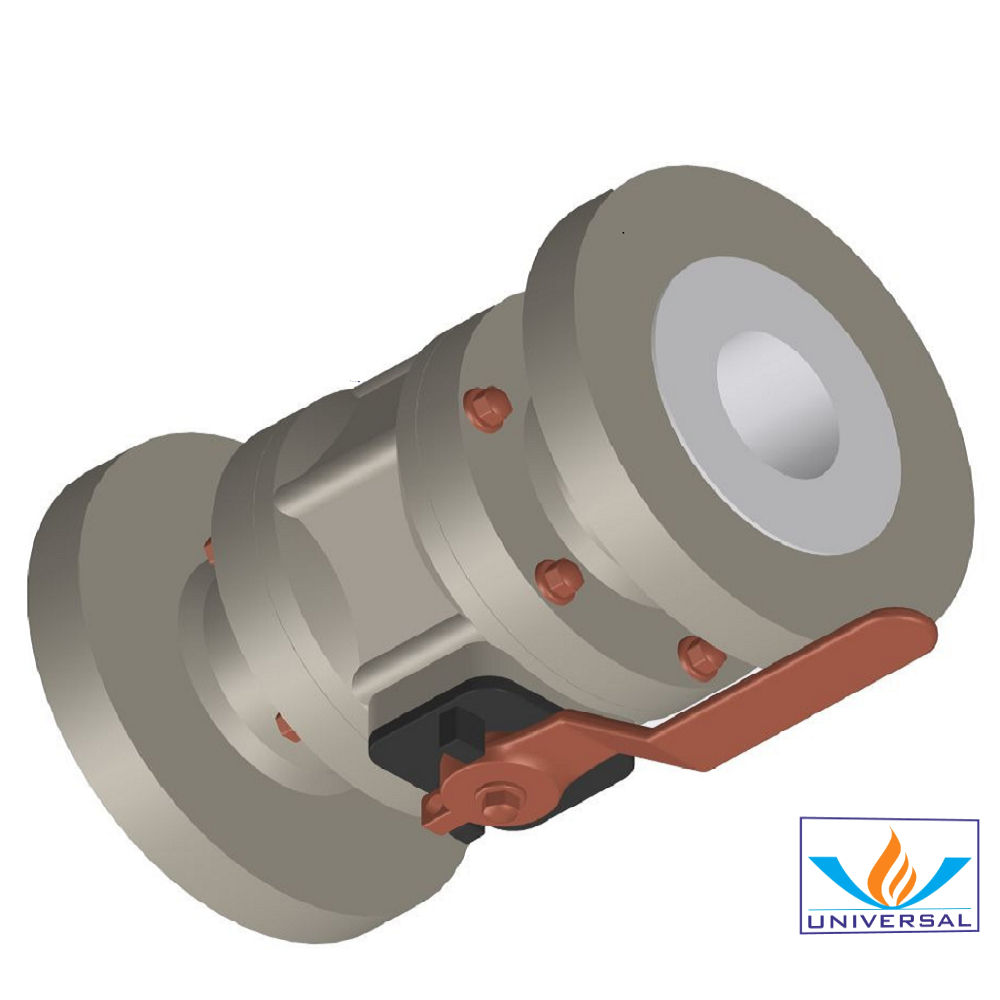

Ball Valve Suitable For Very High. Cons. Chemical Type T8

20400 INR/Number

Product Details:

- Melting Point 160C 170C

- Heat Resistance Yes

- Leak Protection 100% Leak Proof

- Surface Finish Smooth

- UV Resistant Yes

- Plastic Type Industrial Grade PP

- Color Pattern Solid

- Click to View more

X

Ball Valve Suitable For Very High. Cons. Chemical Type T8 Price And Quantity

- 10 Number

- 20400 INR/Number

Ball Valve Suitable For Very High. Cons. Chemical Type T8 Product Specifications

- High

- 0.91 Gram per cubic centimeter(g/cm3)

- 25-35 MPa

- Solid

- Injection Molded

- Industrial Grade PP

- Ball Valve Suitable For Very High Cons. Chemical Type T8

- Yes

- Smooth

- White / Blue

- 1/2 inch to 2 inch available

- Lightweight (depends on size)

- Yes

- Customizable as per requirement

- 100% Leak Proof

- Injection Molding

- Polypropylene (PP)

- 160C 170C

Product Description

High temperature and chemical resistance material. Low operating torque, UV stabilized Iso-PP material to avoid cracks against sunlight., Better resistance to solvents, chemicals and temperatures. Suitable for bromine, Nitric Acid and 98% sulfuric acid.

Construction :3 Piece Design, 1 piece stem (spindle), Full Bore, Seated.

Standard :- As Per Manufacturers Standard

Connection End :-Flanged as per ANSI B 16.5 (150#) & BS 10 (Table D/E/F) & DIN STD.

This valve has a solid PVDF body, solid PVDF Ball, PVDF coated ( Moulded ) SS-316 stem, only two flanged ends have inner liners (moulded 3.75 mm to 5.5 mm thick) of PVDF and on this liners, P Polypropylene flanged ends are molded. So all chemicals comes in contact with PVDF and T Materials only

Body to ends sealing & stem sealing 'O' Rings are of pure. To compress these 'O' Rings Firmly, a steel ring insert of 5mm thick is moulded in flanged ends.

We use virgin imported PVDF and Polypropylene materials of grades that are internationally popular, especially used for manufacturing of valves and fittings.

Reliable Performance in Extreme Conditions

Designed for acidic and highly corrosive environments, the Type T8 Ball Valve offers resistance to chemicals and UV exposure. Its high tensile strength and smooth finish guarantee durability, even under fluctuating temperatures from -10C to +80C. The valve supports operational reliability in continuous-use industrial applications.

Effortless Installation and Ergonomic Operation

Installation is simple with options for threaded (BSP) or socket weld end connections. The quarter-turn closure mechanism, paired with a polypropylene handle, enables smooth, precise control. The lightweight design allows for easy handling and mounting, while the ergonomic grip minimizes user fatigue during operation.

Full Compliance and Leak-Proof Assurance

Tested to meet international standards for chemical resistance and structural integrity, this valve delivers over 25,000 maintenance-free cycles. EPDM/PTFE seals provide complete leak protection, ensuring safe handling of hazardous fluids within pipelines. Each unit is packaged individually in polybags and cartons for added reliability.

FAQ's of Ball Valve Suitable For Very High. Cons. Chemical Type T8:

Q: How does the Ball Valve Type T8 perform under highly corrosive chemical conditions?

A: The Type T8 Ball Valve is constructed with industrial-grade polypropylene (PP) and features EPDM/PTFE seals, delivering excellent resistance against acids and corrosive chemicals. This makes it ideal for pipelines handling aggressive fluids and ensures long-term durability.Q: What installation options are available for this ball valve?

A: You can install this valve using either threaded (BSP) connections or socket welds, allowing flexibility to suit various pipelines in water treatment plants and industrial fluid handling systems.Q: When should this valve be used for industrial applications?

A: This valve is best utilized in settings where fluid control of acidic or highly corrosive substances is required, such as chemical pipelines, water treatment plants, and other industrial systems needing full bore flow and leak-proof assurance.Q: Where can the Ball Valve Type T8 be installed for optimal results?

A: It can be effectively installed in any system exposed to corrosive chemicals, including industrial fluid distribution networks and water treatment facilities. Its customizable length and ergonomic design suit a variety of pipeline configurations from 1/2 inch to 2 inch sizes.Q: What is the process for maintaining this polypropylene ball valve?

A: Thanks to its corrosion-resistant design and rugged sealing materials, the valve requires minimal maintenance. Regular inspection for external buildup is recommended, but its operational life exceeds 25,000 cycles without routine servicing.Q: How does the valve benefit fluid handling operations?

A: The valve's 100% leak protection, full bore design, and chemical-resistant PP construction help maintain system safety and efficiency, reducing downtime and ensuring reliable performance even in continuous and demanding environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email